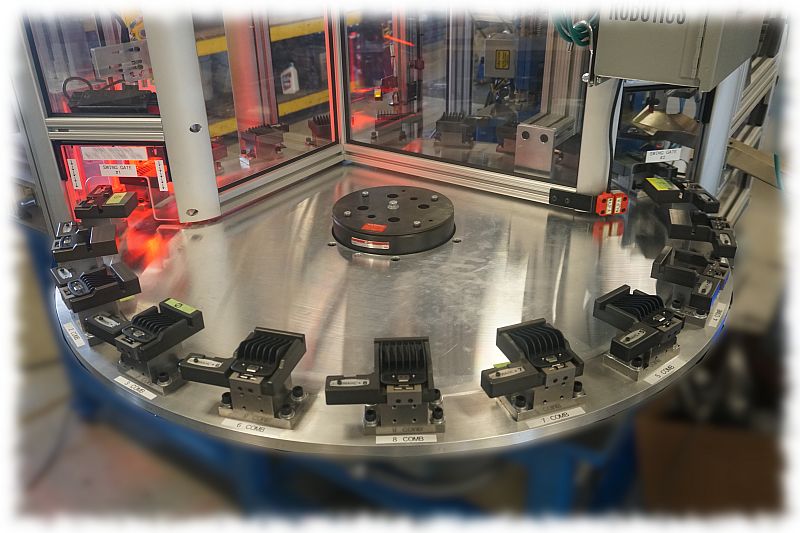

Loading the Dial

The Comb Assembly & Inspection Machine is setup such that an operator load each nest (of 20) with a clip and comb as the center dial continually indexes. The duration between dial cycle intervals is adjustable via the touchscreen and is generally set between 5 and 7 seconds, but could be as low as 3 seconds.

Robot Vision & Plate Placement

A FANUC LR-Mate robot utilizes iRVision to identify which unique comb (1 of 10) is next in-line. After another index the robot picks the associated plate and places it atop the comb. Traveling at full speed to the furthest comb takes just 2.5 seconds from home, to pick, to place and back home. An inline vacuum generator keeps the plate on the robot’s tooling during these fast movements.

Part Present Validation

The machine verifies the comb and plate are present (before they are riveted at the next station). Individual combs can be disabled from being assembled (via the touchscreen). Missing components cycle stop the machine and inform the operator which part is missing.

Comb Assembly

Two rivet machine place rivets to assemble the plate to the comb. The rivet machines automatically load the rivets from a vibratory bowl. The operator is informed via touchscreen when the level of rivets in the bowls are low or when the parts may be jammed.

Assembled Part Verification

A Cognex camera is incorporated to verify the plate and comb are a matching set, the plate is in the correct orientation and both rivets are fastened correctly. External lighting ensures environmental changes do not effect the process. Damaged rivets or a damaged plate cause the system to cycle-stop and the touchscreen reports the issue.

Good Part Removal

Two cylinders, a vacuum generator and a suction cup are used to create simple pick and place ejector. The unit picks and places the combs which have past the part verification into an auto-bagger. The ejector can be configured to skip picking specific combs for additional packaging options.

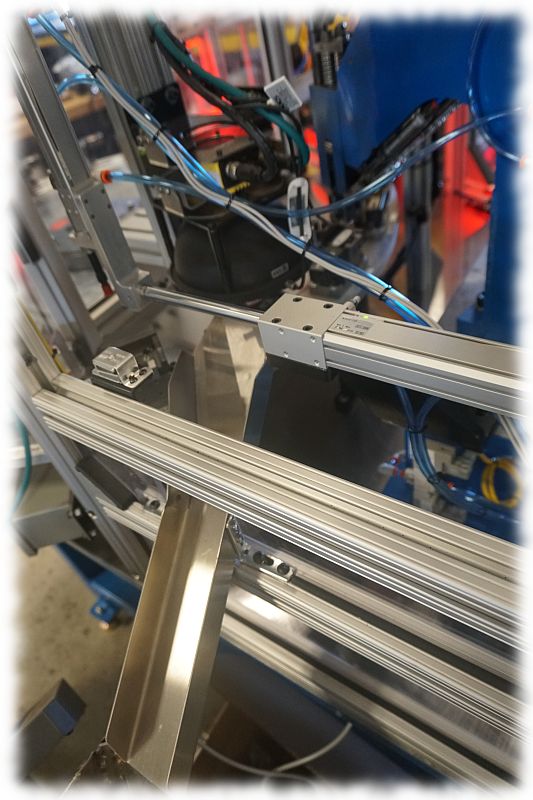

Specifications

- Electricity: 230v AC 1Ø @ 30 Amps

- Pneumatic Pressure: 85 PSI @ 15 CFM

- Machine Size: 6 ft 2 in (L) x 6 ft 1 in (W) x 7 ft 11 in (H)

- Machine Weight: 2,800 lbs

Circuit breakers and relays incorporated for additional circuit protection.

Leave a Reply